the economic sector regularly requires precision, durability, and adaptability in stress checking alternatives. Wholesale Ceramic force Sensor Modules have emerged to be a reliable and cost-successful choice, attaining considerable prominence for demanding industrial programs. underneath, we will check out what can make ceramic sensors distinctive, how they Look at against classic alternate options, and why These are a go-to choice for lots of engineers and brands.

Table of contents:

comprehension Ceramic tension Sensor know-how

sturdiness and dependability in Harsh Environments

Comparing Ceramic Sensor Module to regular stress Sensor Module

knowledge Ceramic stress Sensor engineering

Ceramic strain sensors leverage Superior ceramic elements and reducing-edge engineering to provide very exact force measurements. compared with traditional stress sensors, They can be created specifically to endure adverse environments even though preserving accuracy and steadiness with time. The HXL-XL100 Integrated Ceramic stress pressure sensor modules Sensor Module, For example, highlights this engineering with its compact style and design, solid impact resistance, and substantial-general performance criteria. no matter whether Utilized in HVAC methods, automotive programs, or industrial approach control, ceramic sensors excel in reliability and general performance. These sensors are developed to resist demanding environments and guarantee precise, steady readings over time. With attributes like 150% overload resistance, they are created to handle Severe ailments with out threat of failure. Also, they offer multi-sign output selections, enabling seamless integration into various units, and employ State-of-the-art algorithm payment technological know-how to enhance precision and adaptability. These modules offer custom made alternatives that satisfy unique business wants, all whilst protecting efficiency and staying away from disruptions to operational workflows.

Durability and trustworthiness in Harsh Environments

When it comes to use in rugged environments, ceramic stress sensors deliver unmatched dependability. Industrial configurations frequently deal with Extraordinary temperatures, significant levels of vibration, and corrosive substances. The ceramic sensor modules’ strong building makes certain they work seamlessly below such circumstances. distinct modules similar to the HXL-XL100 are meant to deal with functioning temperatures ranging from -thirty°C to 85°C, even though also featuring resistance towards mechanical overload and electrical instability. Their extremely long lasting ceramic products not simply guard against corrosion but also add to for a longer time operational lifespans as opposed to standard sensors. This will make them an Remarkable option for industries like automotive and HVAC, where by reliable effectiveness in tough settings is important to retaining effectiveness and trustworthiness. Their potential to resist harsh circumstances, which include Excessive temperatures, vibrations, and prolonged use, guarantees they meet up with the demanding requirements of such sectors easily.

evaluating Ceramic Sensor Module to conventional tension Sensor Module

The debate between ceramic sensor modules and classic stress sensors frequently boils right down to precision, toughness, and value-effectiveness. common stress sensors, when purposeful in many scenarios, generally tumble small in Serious environmental circumstances. Non-ceramic sensors can degrade after a while resulting from publicity to corrosive substances or substantial force, resulting in inaccurate readings or technique failures. Conversely, ceramic sensor modules, like All those equipped by Huaxinlian technological innovation, reveal a significant edge due to their design. Their compact character, small electrical power use, and longevity make them Charge-economical over the long run, even when the First expenditure may be increased. Using the presence of innovations which include Highly developed algorithm correction, Improved sensitivity, and customizable output alternatives, ceramic tension sensor modules are getting to be ever more innovative. These options guarantee higher precision, reliability, and flexibility, making them far better suited to fulfill the evolving and numerous requires of contemporary industrial apps. From monitoring fluid amounts to optimizing machinery overall performance, these modules Engage in a important role in ensuring effectiveness and precision across various industries.

Given their precision and adaptability, ceramic tension sensor modules continue to solidify their position in industrial use. When you are a professional seeking robust remedies personalized on your environment, sourcing modules much like the HXL-XL100 from a trustworthy Ceramic stress Sensor Module maker could reshape your overall tension-checking program. Merge this with the knowledge of the Industrial strain Transducer maker, and organizations can fulfill elaborate industrial calls for with effortless efficiency. For wholesale inquiries or to learn more about integrated ceramic tension sensor modules, Get hold of trusted suppliers who focus on offering higher-good quality, trustworthy remedies. These sensor modules are built to resist demanding industrial environments, making sure precise force readings and lengthy-lasting functionality. associate with experts to protected your industrial functions with condition-of-the-artwork engineering that satisfies the necessities of recent applications.

Alexa Vega Then & Now!

Alexa Vega Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Meadow Walker Then & Now!

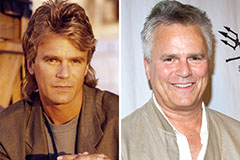

Meadow Walker Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!